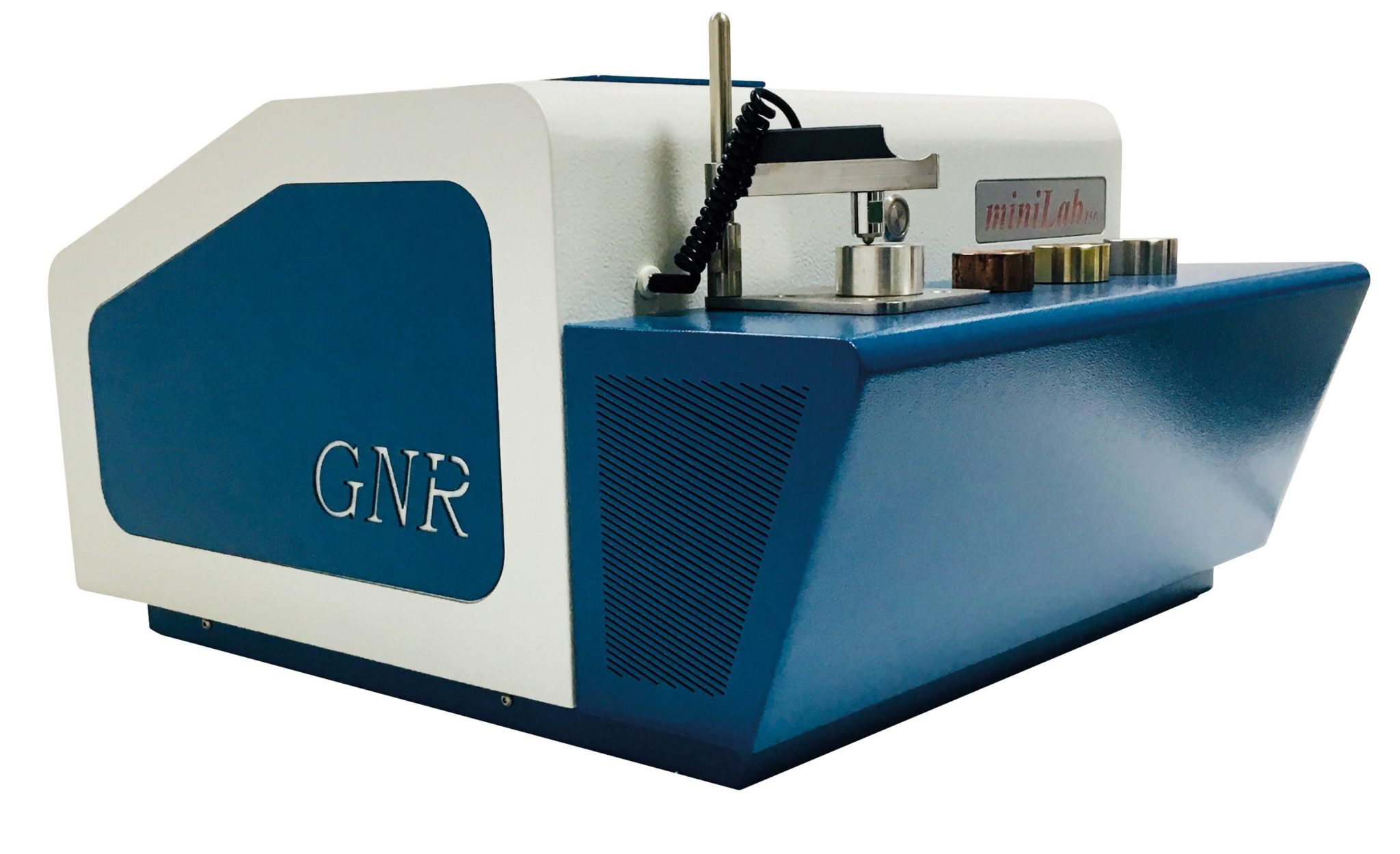

Optical Emissions Spectrometers

Optical Emission Spectrometry (OES) is an analytical technique, universally considered and used to determine the chemical composition of metal alloys.

Thanks to Optical Emissions Spectrometers and their precision and short analysis time, OES represents a valid control system of production in all the fields regarding metal industry (primary alloys foundries, metal processing industries, mechanical industry) in any time during production cycle, in the case it is necessary to have a fast and accurate chemical analysis of material.

Showing 1–9 of 11 results

OES MAINTENANCE & CALIBRATION:

OES MAINTENANCE & CALIBRATION: