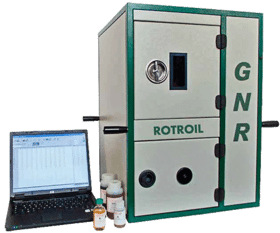

Rotrode Emission Spectrometer

Latest generation and most advanced version of the traditional Rotrode Emission Spectrometer, the perfect spectrometer for the in-service oil analysis laboratory

The R3 RotrOil spectrometer instrument is a compact, transportable and easy to use optical emission spectrometer designed specifically to determine trace concentration in wear metals, polluting materials and additives in lubricating oils, transmission and refrigerating liquids.

Wear Metals & Content

Complaint to the requirements of the ASTM D6595-00 Standard Test Method for determination of Wear Metals and Contaminants, the R3 RotrOil spectrometer can be used for metal analysis of lubricating oils or hydraulic fluids by Rotating Disc Electrode Atomic Emission spectrometry.

ASDM & DOD JOAP

Used in correlation with both ASDM norms and DoD JOAP, the R3 RotrOil Spectrometer can be used for oil conditions monitoring and failure prevention procedure.

Applications

The typical application for the R3 RotrOil Spectrometer is whenever there is the needs for elemental analysis of for preventive maintenance and related cost reduction of lubricating oils, transmission fluids, fuels, hydraulic fluids and greases for wear metals, contaminants, additives and corrosive impurities.

- Military Forces

- Airlines

- Railways

- Marine Fleets

- Companies

- Mines

- Refineries

- Power Plants

- Oil Plants

- Oil Recycler

- Manufacturing Plants

- Commercial Laboratories

- Racing Team

- Public and Private Transportation

OES MAINTENANCE & CALIBRATION:

OES MAINTENANCE & CALIBRATION: