Description

APD 2000 PRO diffractometer is an high power – Theta/2Theta – laboratory powder X-Ray Diffractometer equipped with all the most moder technical features which grant accuracy, precision, safety and easiness of use for XRD analysis of polycrystalline materials.

Thanks to a wide offer of configurations and accessories such as high-speed detector, scintillation counter, high-low temperature and humiduty chamber, secondary monochromator, spinner and multiple sample holder, APD 2000 PRO is a powerful tool for powder diffraction applications such as routinary qualitative and quantitative phase analysis, non-ambient analysis, structure solution and refinement, crystallite size and degree of crystallinity calculation.

- High Speed Rate (1000°/min)

- High Precision Angle Reproducibility (+/- 0.0001°)

- Fast Measurement and Highly Reliable Data

- Extremely precise angular values thanks to stepper motors with optical encoders

Easy to handle

Features

- Qualiltative and Quantitative Powder X-Ray Diffractometer

- High Stability X-Ray generator through precision feedback control circuits

- Automatic ramp of the high voltage and emission current to preset values

- Ceramic X-Ray tubes with high reproducibility and stability of focus position

- Microfocus tubes and policapillary collimators

- Possibility of changing automatically from transmission to reflection mode

- High precision, high speed goniometer controlled by optical encoders

- Traditional, rotating, multi sample and capillary sample holders

- Scintillation counters, silicon strip and energy dispersive detectors

- Non-ambient analysis, low and high temperature chambers, humidity device

![]()

Software

Data collection Programs

GNR offers a large variety of acquisition programs, for standard as well as for customized hardware configurations. The list includes the programs for powder and high resolution diffractometers, retained austenite, data acquisition of stress (plane and triaxial) and thin films (XRR and GID). The programs can control: X-ray generator and tube, instrumental alignment, multi purpose sample holder, scintillation counter, linear silicon strip detector, solid state detectors, high/low-temperature, humidity chambers and other devices.

SAX

Single peak analysis; peak treatment. Background subtraction, smoothing, deconvolution and peak localisation. Structural Analysis, Crystallite Size, Lattice Strain, Reflectometry, Quantitative Analysis.

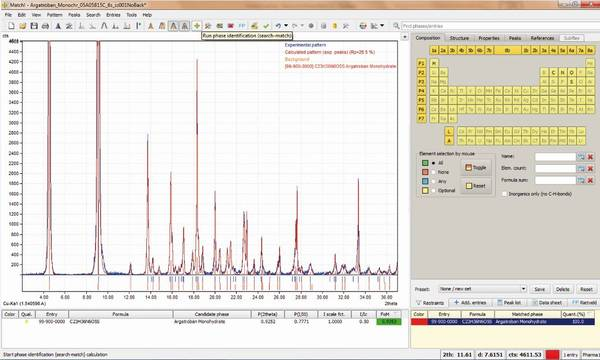

Search and Match: MATCH!

Rietveld refinement, Display and compare multiple diffraction partners, Directly view specific phases/entries, instant usage of additional information, saving of selection criteria, Comfortable definition of background, Improved zooming facilities, Batch processing and Automatics.

Applications

Qualitative and quantitative phase analysis, non-ambient analysis, retained austenite quantification, structure solution and refinement, crystallite size and crystallinity calculations.

- Geology and Mineralogy / Clays

- Glass / Ceramics / Cement

- Chemicals / Petrochemicals

- Catalyst / Polymers

- Forensics

- Agricultural Sciences

- Biosciences / Environmental

- Pharmaceuticals

- Cosmetics

- Art and Archeology

![]()

Installation Requirements

Electrical System

- Power connection: 220 Vac +/- 10%, 50 or 60 Hz, single phase

- Maximum mains current: 40 A

- Main fuse: 32 A

- Maximum power consumption: 5 kVA

- Ground terminal: 6 mm 2

Power supply voltage fluctuation must not exceed 10%

Cooling Water

- Minimum flow rate: 4 l/min

- Maximum pressure: 6 bars

- Maximum inlet temperature: 35° C (minimum depends on dew point)

If the flow rate is lower than 4 l/min, the safety circuit for protection of the X-ray tube is activated, disabling the X-ray generating circuit. When minimum conditions of flow-rate cannot be fulfilled, use the water chiller, available as an optional extra.

OES MAINTENANCE & CALIBRATION:

OES MAINTENANCE & CALIBRATION: